HONEYWELL Interruttori di pressione e vuoto Progettato per aprire/chiudere rapidamente il circuito quando la pressione supera il set point designato. Sono dotati di un involucro in poliestere rinforzato con vetro per una maggiore durata e di un attuatore a membrana per rilevare la variazione di pressione. Disponibile nelle varianti ad azione standard e inversa.

Progettato per aprire/chiudere rapidamente il circuito quando la pressione supera il set point designato. Sono dotati di un involucro in poliestere rinforzato con vetro per una maggiore durata e di un attuatore a membrana per rilevare la variazione di pressione. Disponibile nelle varianti ad azione standard e inversa.

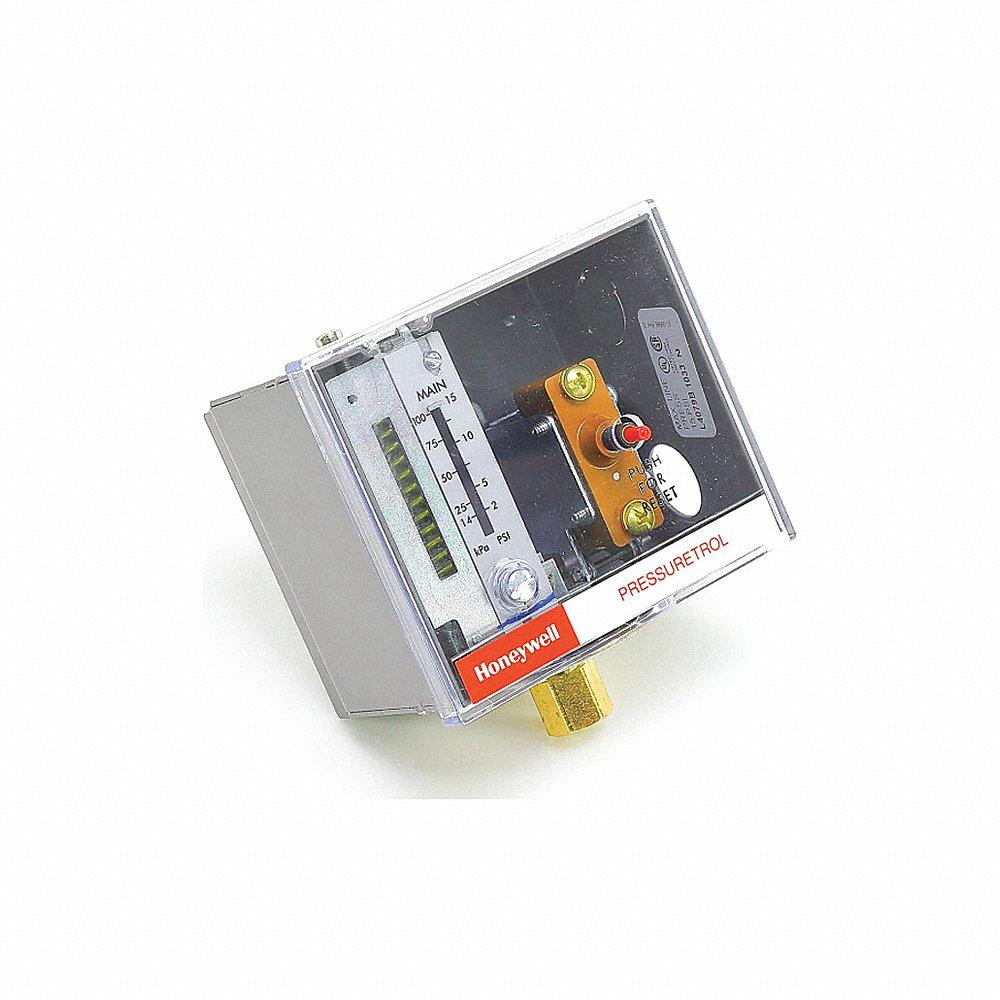

Pressostato

I pressostati Honeywell vengono utilizzati per fornire feedback elettrico in risposta a una camera che sale o scende a un livello di pressione predeterminato. Queste pezzo sono dotate di un involucro in poliestere rinforzato con fibra di vetro con una connessione terminale a vite in grado di effettuare regolazioni sul campo e un diaframma in Kapton compatibile per l'uso con un'ampia varietà di fluidi. Sono inoltre progettati per funzionare in combinazione con diverse terminazioni (connettore Metri-Pack) che formano una tenuta ermetica una volta collegati. Scegli tra un'ampia gamma di questi pressostati disponibili nelle varianti con pressione di scoppio da 750 PSI e 1250 psi su Raptor Supplies.

I pressostati Honeywell vengono utilizzati per fornire feedback elettrico in risposta a una camera che sale o scende a un livello di pressione predeterminato. Queste pezzo sono dotate di un involucro in poliestere rinforzato con fibra di vetro con una connessione terminale a vite in grado di effettuare regolazioni sul campo e un diaframma in Kapton compatibile per l'uso con un'ampia varietà di fluidi. Sono inoltre progettati per funzionare in combinazione con diverse terminazioni (connettore Metri-Pack) che formano una tenuta ermetica una volta collegati. Scegli tra un'ampia gamma di questi pressostati disponibili nelle varianti con pressione di scoppio da 750 PSI e 1250 psi su Raptor Supplies.

| Style | Modello | Action | Pressione di scoppio | Modulo di Contatto | Impostazione di accensione / spegnimento di fabbrica | NEMA | Escursione | Prezzo | |

|---|---|---|---|---|---|---|---|---|---|

| A | 76575-B00000040-01 | €122.19 | |||||||

| A | 76052-B00000150-01 | €120.99 | |||||||

| A | 76576-B00000100-01 | €115.26 | |||||||

| A | 76055-B00001000-01 | €128.27 | |||||||

| A | 76051-B00000020-01 | €112.94 | |||||||

| A | 76053-B00000300-01 | €123.02 | |||||||

| B | 76054-B00000600-01 | €120.03 | |||||||

| B | 76061-B00000020-01 | €132.79 | |||||||

| B | 76064-B00000600-01 | €153.64 | |||||||

| A | 76577-B00000040-01 | €135.10 | |||||||

| A | 76580-B00000100-01 | €139.49 | |||||||

| A | 76072-B00000150-01 | €160.28 | |||||||

| A | 76074-B00000600-01 | €140.08 |

Pressostati

| Style | Modello | Prezzo | |

|---|---|---|---|

| A | C6097A3012 | €331.75 | RFQ |

| B | C6097A3004 | €301.00 | RFQ |

| C | 76055-00001000-01 | €164.93 | RFQ |

| D | L4079B1033 | €357.00 | RFQ |

Caratteristiche

- Honeywell pressure switches feature a glass-reinforced polyester enclosure for durability and a diaphragm actuator to sense the pressure change.

- These units have a Kapton diaphragm compatible for use with a wide variety of fluids.

- They are further designed to work in conjunction with different terminations (Metri-Pack connector) which forms a tight seal when connected.

- They are available in 750 PSI and 1250 psi burst pressure variants.

Meccanismo di lavoro

- Apply pressure or vacuum to the sensing element.

- Sensing element deforms in response to pressure or vacuum.

- This causes the movement of a diaphragm or piston and activates a switch mechanism.

- The switch mechanism then completes or interrupts an electrical circuit based on the pressure or vacuum level.

- Finally, the electrical circuit controls associated equipment or triggers alarms.

Domande frequenti

How do I install Honeywell pressure and vacuum switches?

- Securely mount the switch using appropriate fasteners, ensuring it is positioned correctly.

- Connect the electrical wiring to the terminals of the pressure or vacuum switch according to the wiring diagram provided.

- Test the operation of the switch to ensure it functions correctly and responds appropriately to changes in pressure or vacuum.

- If required, adjust the switch settings according to the application requirements.

- Once tested and adjusted, securely fasten any connections and ensure they are properly insulated.

- Conduct a final inspection to verify that the switch is installed correctly and is ready for use.

What factors should I consider while choosing a pressure and vacuum switch?

- Select a switch with the necessary accuracy to meet your operational requirements.

- Determine if the switch allows for easy adjustment of setpoints to accommodate varying pressure or vacuum levels.

- Consider the response time of the switch to ensure it reacts quickly to pressure or vacuum changes as needed.

- Assess the operating environment for factors such as temperature, humidity, and exposure to corrosive or hazardous substances, and choose a switch that can withstand these conditions.

- Ensure the switch's electrical rating matches your system requirements to prevent overload or failure.

- Choose a switch with mounting options suitable for your application, whether it's panel mount, pipe mount or other configurations.

- Select a switch from a reputable manufacturer known for producing reliable and durable products to minimise the risk of failure.

- Check if the switch meets industry standards and certifications relevant to your application, such as UL, CE or CS

What safety precautions should I take while using a pressure and vacuum switch?

- Operate the switch within specified temperature, humidity and environmental conditions outlined in the manual to prevent damage or malfunction.

- Follow electrical safety procedures when connecting the switch to power sources, such as turning off the power before installation, using insulated tools and wearing appropriate personal protective equipment.

- Do not exceed the maximum pressure or vacuum rating of the switch to prevent damage or failure.

- Periodically inspect the switch for signs of damage, wear or corrosion and replace any worn or damaged components promptly.

- Establish procedures for emergency shutdown in case of switch malfunction or unexpected pressure / vacuum conditions.

Siamo qui per aiutare!

Cerchi una parte non elencata qui?

Esplora di più

- Filtrazione

- Training

- Insetticidi e controllo dei parassiti

- ventilazione

- Pannelli solari e accessori

- Pentole di scarico e gocciolamento

- Sistemi di monitoraggio wireless

- Strumenti di scarico del filo

- Carrelli elevatori e accessori per carrelli elevatori

- Radiatori dell'olio ad aria forzata offline

- ACCUFORM SIGNS Etichetta di pericolo, cartoncino PF da 10 mil, 5-3 / 4 "x 3-1 / 4"

- WESCO Carrelli di servizio in acciaio

- RULE Pompa, sommergibile

- ELVEX Serie RX-200, occhiali da lettura

- COOPER B-LINE Guide Rite Series Conduit to piedistallo

- WESTWARD Gruppo tappo, 1/4s

- TB WOODS Giunti a disco flessibili serie D

- VESTIL Basi opzionali serie JIB-CB

- TRI-ARC Scale mobili perforate per prelievo titoli

- SPEEDAIRE Piastre posteriori